Air Services company is proud to offer Elmo Rietschle blower and vacuum technologies. Air Services Companies’ dedicated vacuum and blower specialist’s work diligently to aid the customer in selecting the right technology for their industry and application.

F-Series – Radial

Radial fans are mainly used in the packaging and paper industries, with the smaller units used for extracting dust with fine material such as paper powder and powdered solids.

F-CEV-S

Radial blowers with three to five stages for vacuum operation

Capacities up to 328 cfm and vacuum up to 46.2 in. H2O.

Compact design, low temperature operation even when throttled. Fast start-up due to light weight impellors.

F-CEV-D

Radial blower with three to five stages for pressure operation

Capacities up to 328 cfm and pressure up to 50.2 in. H2O.

Compact design, low temperature operation even when throttled. Fast start-up due to light weight impellors.

F-CEVF (29)

Multi stage radial blowers for vacuum operation

Capacities up to 177 cfm. Total pressure difference up to 36 in.

H2O. Complete with filter and dust separator. Suitable for removing paper powder and dust.

F-CEVF (31)

Multi stage radial blowers for vacuum operation

Capacities up to 275 cfm. Total pressure difference up to 28 in.

H2O. Complete with high filter vessel and collection bin. Suitable for removing paper, film or plastic trim scrap.

F-RER / F-REL

Single stage radial blowers for vacuum and pressure operation

Capacities up to 2,013 cfm and vacuum up to 38.3 in. H2O, pressure up to 39.9 in H2O.

Solid light weight construction. Vibration free and quiet running. The bearings are greased for life and need no servicing. Available in left or right hand configurations for maximum installation flexability.

G-Series – Side Channel

G-BH1 00

The smallest regenerative blower on the market

With a height and width of approximately 4.9 inches and a depth of approximately 2.4 inches, the G-BH1 00 blowers are the smallest regenerative blowers available on the market.

G-BH1

Classic with innovative technology

With their high inlet volume flow up to 1,413 cfm and a differential pressure of up to 313 in. H₂O, our low noise G-BH1 regenerative blowers have earned their reputation. They are reliable, low maintenance and durable. They deliver 20,000 operating hours between service and are virtually maintenance free.

G-BH2 VELOCIS

The regenerative revolution

Volume flow up to 520 cfm and differential pressure up to 420 in. H₂O. With its significantly expanded range of performance and lower noise levels, the regenerative technology can now be used in completely new fields of application that were previously inconceivable. They deliver 40,000 operating hours between service and are virtually maintenance free.

G-BH7

Unsurpassed at highest differential pressure

Our high performance G-BH7 regenerative blowers can create differential pressure of up to 435 in. H₂O. They deliver 20,000 operating hours between service and are virtually maintenance free.

L-Series – Liquid Ring

L-BL2

Also known as the Elmo Rietschle

Pump in a Box, these selfcontained portable units are oil free and air cooled. They include an L-BV liquid ring pump, industrial electric motor, discharge separator, heatexchanger and discharge condenser.

To install, simply connect the suction line and motor and fill the water tank—its ready to go!

L-BV3

Performance strength in the smallest space

The L-BV3 liquid ring vacuum pumps are remarkable—whether they are used for sterilizers or for medical / laboratory equipment, they excel where extremely small suction capacities are required within a minimum of space. With a suction volume of up to 6.18 cfm, these little workhorses are particularly quiet and consume very little water. The L-BV3 can handle suction vapors and liquids.

L-BV7 / L-BV2

Multi-purpose liquid ring pumps

Our L-BV7 and L-BV2 liquid ring pumps are high-efficiency machines which save space and consume up to 50 % less water. These pumps are available in various combinations of materials such as stainless steel, bronze, ceramic and cast iron with a ceramic coating. This enables them to be tailored to the respective operating requirements and thus provides long term resistance to corrosion.

L-BV5

Monoblock pumps with the highest volume flow

The L-BV5 family is characterized by a very high suction volume

of up to 353 cfm with suction pressures of up to 29 inHg and are primarily used for applications with large quantities of liquids

(2BV54). The L-BV5 also simultaneously works as a condenser while suctioning condensable vapors. This enables the suction volume to be doubled. Reinforced stainless steel shafts, continuously lubricated bearings and a coated pump housing prevent wear and tear caused by solids that are also ingested, and guarantee constant performance, even after many years of use.

V-Series - Rotary Vane

Oil-Less Rotary Vane Vacuum Pumps

V-VTE

Capacities ranging from 2 to 7 cfm, ultimate vacuum

25.5 inHgV. Compact, easy to install. Very low noise level. Corrosion resistant rotors. Hose connection and exhaust silencer as standard.

V-VTN

Capacities from 8 to 30 cfm, ultimate vacuum of 25.5 inHgV. Sound cover reduces noise level, enhances cooling and protects operator from touching hot surfaces.

Comes with built-in suction filter and vacuum valves. Low vibration, easy to operate, install and service.

V-VTR

Capacities from 39 to 91 cfm, ultimate vacuum of 25.5 inHgV. Bearings on both sides of the rotor. Flange mounted motor with bolt coupling. High efficiency and

low noise operation. Sound cover allows a ducted cooling air outlet either from one side only or from both front and back. (60–80 size) Easy to operate and service.

Oil-Less Rotary Vane Compressors

V-DTE

Capacities from 2 to 7 cfm, pressure up to 14.5 psig. Compact design, easy to build into machines, very low noise level. Hose connector, inlet silencer and pressure relief valve fitted as standard.

V-DTR

Capacities from 36 to 91 cfm, pressure up to 22 psig for continuous operation and up to 32 psig for intermittent operation. Bearings on both sides of the rotor. Flange mounted motor with bolt coupling. High efficiency and low noise operation. Sound cover allows a ducted cooling air outlet, from one side. Easy to operate and service.

Oil-Less Rotary Vane

Pressure-Vacuum Pumps

V-KTR

Capacities from 28 to 95 cfm, vacuum up to 18 inHgV, pressure up to 10 psig. High efficiency and low noise level. Sound cover allows a ducted cooling air outlet. Easy to operate and service.

C-Series - Claw

C-VLR ZEPHYR

Claw vacuum pumps

Capacities ranging from 42 to 353 cfm and maximum continuous vacuum up to 27 in. HgV. Highly efficient, oil-less and contact free operation. Excellent pumping capacities throughout the entire vacuum range.

Integrated air cooling without the need for water cooling. Available with optional variable speed drive.

Low maintenance; wide range of applications.

C-DLR ZEPHYR

Claw compressors

Capacities ranging from 42 to 353 cfm; maximum pressure in continuous operation up to 32 psig. Highly efficient, oil-less and contact free operation. Excellent pumping capacities throughout the entire vacuum range. Integrated air cooling without the need for water cooling. Available with optional variable speed drive. Low maintenance; wide range of applications. ATEX versions available for biogas or methane compression.

C-KLR ZEPHYR

Claw combination pressure-vacuum pumps

Capacities ranging from 57 to 82 cfm. Vacuum up to 18 in. HgV and pressure up to 10 psig. Highly efficient, oil-less and contact free operation. Vacuum and pressure operating points are virtually independent of each other with excellent flow capabilites. Integrated air cooling without the need for water cooling.

Integrated after cooler for low temperature compressed air delivery. Low maintenance; wide range of applications.

S-Series – Screw

VSI Twister

Capacities from 71 to 212 cfm, maximum end vacuum 29.917 inHg (0.075 Torr). Continuous variable-pitch screws ensure the highest efficiency of operation. Progressive graduation of the screw pitch. Maximum sealing thanks to labyrinth, shaft and piston ring seals. Sealing gas is optional. Benefits include low noise, low operating temperatures and easy serviceability. Designed for industrial applications devoid of aggressive gases.

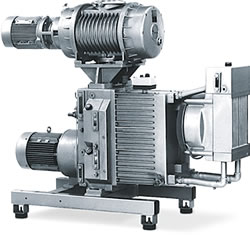

R-Series – Rotary Lobe

These compact rotary lobe blowers belong to the group of dry running positive displacement pumps. This means that there is no need for oil or grease in the compression chamber. Only gear box and bearings, which are separated from the pumping chamber, are oil lubricated. Two non contacting triple lobed rotary lobe rotors rotate against each other in the compression room.

The triple lobed rotors avoid pulsation problems. The blowers are customized to cater for the varying demands of our customers‘ applications.

R-VPA Vacuum Pumps

- Pump sets consisting of V-VWZ and rotary lobe pumps.

- They combine the advantages of fresh oil lubricated vacuum pumps with the high suction capacity of a rotary lobe pump. Primarily used for generating fine vacuum in general industrial applications and for chemical processes.

- ATEX compliant versions are available on request.

R-VPR Vacuum Pumps

- Pump set consisting of a V-VC rotary vane in combination with a rotary lobe vacuum pump.

- Primarily used for production of fine vacuum for general industrial applications.

- Ultimate vacuum of 0.01 mbar (abs) possible.

R-WVB Vacuum Pumps

- Dry running two (R-WVB 25) or three (R-WVB 120) lobed rotary blowers.

- Designed for use with vacuum operations up to a maximum of 0.5 bar (abs).

- The variable capacity blowers cover a range from 22 to 8,580 m³/hr (12.9 to 5,049.4 cfm) in 16 sizes.

- Low noise level and low pulsation.

- High efficiency due to optimal speed.

- Robust design.

- Easy to service.

X - Series - Systems

Air Supply Cabinets

- Optimized installation and operation costs.

- Reduction of heat and noise emission in the production area.

- Optimal coordination and control of the operation of all components.

- Simplified maintenance of single components due to the central installation.

- Small footprint.

Customized Systems

- Blast air and vacuum supply for applications in printing and paper industries

- Lifting, holding, handling and clamping

- Conveying

- Distillation

- Evacuation of industrial furnaces

- Packaging

- Impregnation

- Degassing of sintered material

- Cooling

Plug and Play Solutions

The Elmo Rietschle rotary vanes are also available as central vacuum units for industrial applications. They come complete with control panel as plug & play solutions.

Features:

- Single stage air cooled oil lubricated rotary vane vacuum pumps

- Installled on a rack

- Includes control panel

- Isolation class F protection class 55

- Wear-free vanes

- Low noise level

- Easy access to filter elements for service

Standard Systems

LIQUID RING UNITS L-SV

For stable operation, liquid ring pumps must be permanently supplied with liquid, which escapes with the conveyed gas on the discharge side.

That is why we have developed standardized circuit units as system solutions, which feed the operating liquid that escaped on the discharge side completely or partially back into the pump.

Circuit units are available for the full range of Elmo Rietschle liquid ring pumps, with ATEX certification and in stainless steel or cast iron.

Partial circuit

To avoid the heating of operation liquid, only the required part of fresh water is delivered to the pump – against the compression capacity of the pump – that is needed for temperature constancy.

Closed circuit

The liquid circuit is cooled by a heat exchanger. Process gases/vapours stay in the circuit, so contaminated sewage and consumption of fresh water is avoided.

VACUUM PUMP UNIT X-SC

Liquid Ring Units L-SV

For stable operation, liquid ring pumps must be permanently supplied with liquid, which escapes with the conveyed gas on the discharge side.

That is why we have developed standardized circuit units as system solutions, which feed the operating liquid that escaped on the discharge side completely or partially back into the pump.

Circuit units are available for the full range of Elmo Rietschle liquid ring pumps, with ATEX certification and in stainless steel or cast iron.

Partial circuit

To avoid the heating of operation liquid, only the required part of fresh water is delivered to the pump – against the compression capacity of the pump – that is needed for temperature constancy.

Closed circuit

The liquid circuit is cooled by a heat exchanger. Process gases/vapours stay in the circuit, so contaminated sewage and consumption of fresh water is avoided.

Vacuum Pump Unit X-SC

The vacuum pump units X-SC are a combination of an air-cooled liquid ring circuit unit with patented discharge-air cooling system of the L-Series (L-BL2) and a side channel blower of the G-Series. So the suction capacity in a pressure range of 30 to 120 resp. 200 mbar is multiplied. The aggregates have a robust design, high vapour compatibility as well as an oil-free compression without contact.

The side channel blower can work at a consistent speed or a frequency converter can be used to enhance the performance of the unit. The operating point can thus be optimized for the application (i.e. pressure constancy control).

Application Brochures

- BioGas

- Environmental

- Glass

- Industrial Parts Cleaning

- MVC - Vaccum Station for Medical Technology

- MVL - Vacuum Station for Medical Technology

- Vacuum and Pressure Solutions for Food Packaging

- Vacuum and Pressure Solutions for Non-Food Packaging

- Plastics

- Printing and Paper

- Process

- Woodworking

.jpg)